End mills are rotating cutting tools used in milling machines to remove material from a workpiece, capable of cutting in all directions unlike drills which cut only axially. They feature cutting edges on the end and sides, making them versatile for precision machining tasks.

Design Features

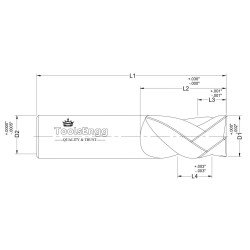

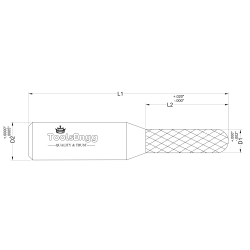

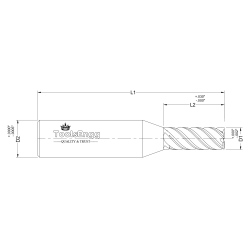

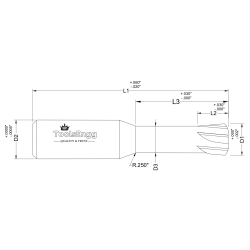

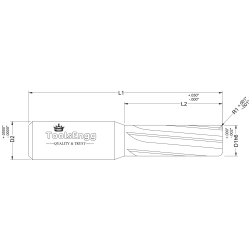

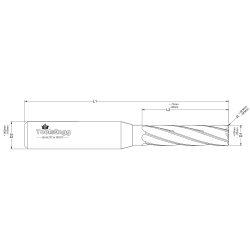

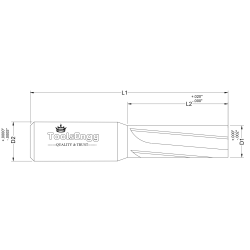

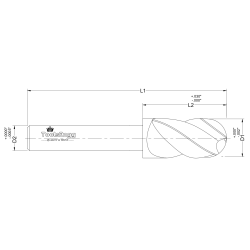

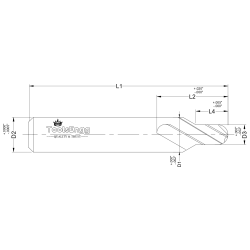

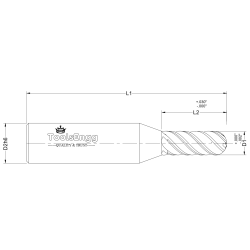

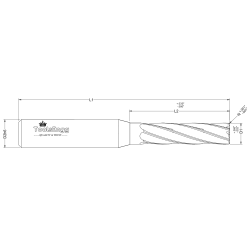

End mills come in various types like square (flat-end), ball-nose, tapered, roughing, and finishing, distinguished by flute count, helix angle, and material such as carbide or high-speed steel. Multiple flutes aid chip evacuation, while coatings enhance wear resistance and heat dissipation. Square ends produce 90-degree cuts, ball ends create smooth contours, and roughing types have serrated edges for heavy material removal.

Key Applications

These tools perform profile milling, slotting, contouring, face milling, plunging, drilling, and reaming across industries. In mold and die making, they craft cavities and 3D shapes; automotive uses include engine parts and transmission housings; aerospace applies them for contoured components. They also serve medical devices, woodworking, and general fabrication for slots, pockets, and threads.

Advantages in Machining

End mills enable high-precision features like grooves, fillets, and undercuts with efficient material removal rates. Variable flute counts balance chip load and finish quality, while specialized designs reduce vibration for smoother surfaces. They boost productivity in CNC operations by handling both roughing and finishing in one setup.