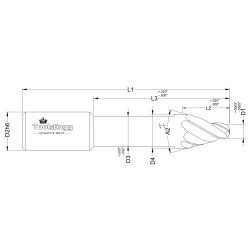

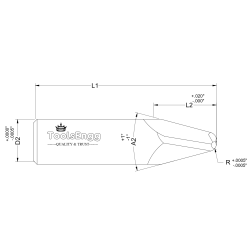

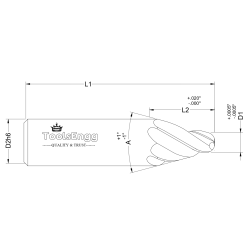

Tapered end mills are specialized milling cutters with a conical shape, narrower at the tip and widening toward the shank, unlike straight end mills. They enable precise machining of angled surfaces, slots, and contours in hard-to-reach areas.

Design Features

The tapered profile provides greater strength, reduced deflection, and better chip evacuation during operation. Flutes on the cutting head carry away debris, minimizing damage to the tool or workpiece. Materials like carbide or high-speed steel enhance durability for high-speed feeds.

Key Applications

Tapered end mills excel in mold and die fabrication, creating angled walls, pockets, and draft angles. They suit aerospace, automotive, and medical manufacturing for contouring, side milling, and reaming conical holes. Use them for deep cavity profiling where straight tools fail.

Advantages Over Standard End Mills

These tools generate less heat, extend tool life, and cut cycle times by allowing deeper reaches with rigidity. The design improves access to tapered features, boosting productivity in precision work. Variable pitch options reduce harmonics for smoother finishes