Composite drills are specialized drilling tools engineered for machining composite materials like carbon fiber, fiberglass, and laminates, featuring geometries that prevent delamination, fiber pull-out, and excessive heat buildup. Unlike standard twist drills, they prioritize clean entry and exit holes with minimal material damage in abrasive, layered structures.

Design Features

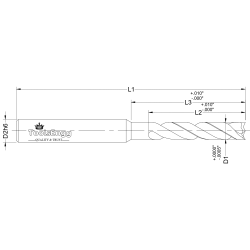

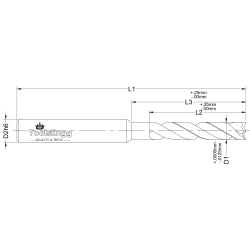

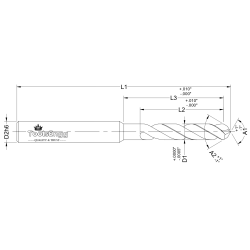

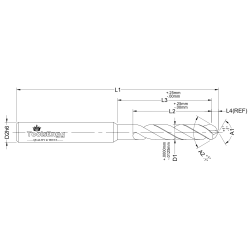

These drills often use solid carbide or diamond-coated construction with sharp, polished flutes for efficient dust evacuation and reduced friction. Key geometries include double-angle points (e.g., 130° primary and 60° secondary angles), brad points for fibrous composites, or multi-facet designs to minimize peel-up and push-out. Coolant-through channels, variable helix angles, and coatings like TiAlN enhance tool life in high-abrasion environments.

Key Applications

Composite drills serve aerospace for fuselage and wing panel holes, automotive for lightweight chassis components, and wind energy for turbine blades. They excel in stacked materials (e.g., CFRP-titanium hybrids), boat hulls, sporting goods like golf shafts, and electronics enclosures requiring precise fastening holes. Ideal for high-volume production where hole quality affects structural integrity.

Advantages Over Standard Drills

They deliver superior hole quality with less delamination, enabling higher feed rates and longer tool life in abrasives that wear HSS rapidly. Optimized for peck drilling and low-thrust entry, they reduce scrap rates and secondary operations while supporting dry or minimal quantity lubrication. Enhanced rigidity suits CNC machines for consistent results in thin or thick laminates.