Material Specific Drills: Optimized Precision at ToolsEngg.com

Material specific drills deliver superior performance by tailoring geometry, coatings, and substrates to individual workpiece materials like steel, stainless, aluminum, or titanium. Available at ToolsEngg.com, these carbide tools boost CNC efficiency for Indian exporters and global machinists.

What Are Material Specific Drills?

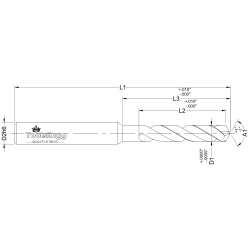

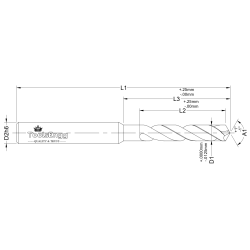

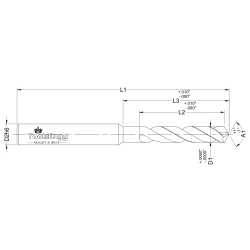

These solid carbide drills feature customized designs for optimal chip evacuation, heat resistance, and wear in targeted alloys. For instance, stainless steel variants use Perrox or TiN coatings to combat work-hardening, while aluminum types have polished flutes to prevent adhesion. ToolsEngg.com stocks diameters from 0.8mm to 32mm for versatile applications.

Key Advantages

Engineered for high feed rates and deep holes, they extend tool life by 2-3x over general-purpose drills, reducing costs in demanding operations. Precision geometries ensure burr-free holes, minimizing rework in aerospace and automotive parts. Enhanced thermal conductivity lowers friction, enabling faster production without edge breakage.

Applications Across Industries

Ideal for drilling high-temp alloys (Ti-6Al-4V), Inox steels, or non-ferrous metals in mold making, medical devices, and heavy machinery. They excel in stacked composites or tough materials, supporting export-quality fabrication at ToolsEngg.com.