Reach Drills: Deep Hole Precision at ToolsEngg.com

Reach drills, also known as deep-hole drills or extended-length drills, enable precise penetration beyond standard 3-5x diameter depths in CNC machining. Perfect for oil galleries, firearm barrels, and hydraulic components, ToolsEngg.com supplies these carbide tools for high-volume export manufacturing.

What Are Reach Drills?

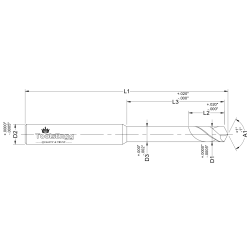

These specialized drills feature elongated flutes, internal coolant channels, and reinforced shanks to handle aspect ratios up to 20x diameter without deflection or breakage. Unlike standard twist drills, reach drills use peck cycles and high-pressure coolant for chip evacuation, ensuring straightness in tough materials like stainless steel or titanium. ToolsEngg.com offers diameters from 2mm to 25mm with custom lengths.

Key Advantages

Reach drills cut cycle times by eliminating multiple short drills or gun drills, boosting throughput in aerospace and automotive production. Advanced geometries reduce thrust forces by 40%, extending tool life while maintaining tolerances under ±0.01mm. Through-tool coolant prevents recast layers, ideal for interrupted cuts on inclined surfaces.

Applications in Industry

Essential for deep blind holes in engine blocks, molds, and medical implants, they excel in stacked materials or cross-holes. In export-oriented machine shops, reach drills support just-in-time delivery with minimal rework.