Spotting Drills: Precision Hole Starting at ToolsEngg.com

Spotting drills create accurate indentations to guide twist drills, preventing wandering and ensuring precise hole locations in CNC machining. Essential for aerospace, automotive, and mold making, ToolsEngg.com offers premium carbide spotting drills for export-quality performance.

What Are Spotting Drills?

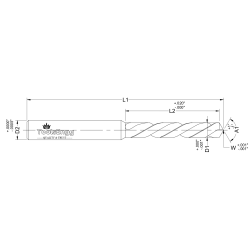

These rigid, short tools feature conical points with 90°, 120°, or 142° angles matching follow-up drills, producing shallow divots up to 1-2x diameter depth. Unlike center drills, spotting drills prioritize guidance over centering, with minimal flutes for stability on mills and lathes. ToolsEngg.com stocks HSS and coated carbide versions from 3mm to 20mm diameters.

Key Advantages

Spot drills reduce drill breakage by 70%, improve hole accuracy to ±0.01mm, and boost cycle times by eliminating rework. Their rigidity handles hard materials like stainless steel or titanium without deflection, while polished surfaces enhance chip flow. Versatile for countersinking, chamfering, and engraving, they extend tool life in high-volume production.

Applications in CNC Operations

Ideal for flat/uneven surfaces, stacked composites, or angled entries in engine blocks, transmission housings, and medical parts. In precision machine shops, they ensure consistent hole placement for taps and reamers.