Hard Milling Long Reach End Mills: Deep Precision at ToolsEngg.com

Hard milling long reach end mills tackle tough materials like hardened steels and alloys with extended flutes for deep cavity work in CNC machining. ToolsEngg.com supplies these variable helix carbide tools, optimizing export manufacturing for molds, dies, and aerospace components.

What Are Hard Milling Long Reach End Mills?

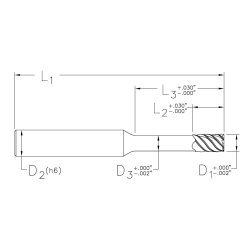

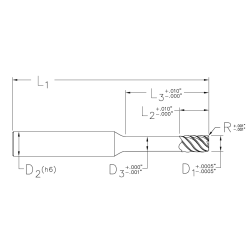

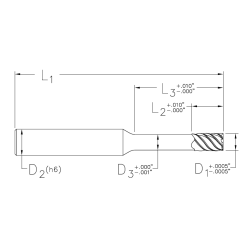

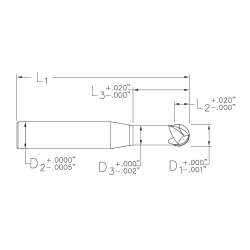

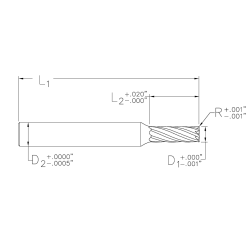

These solid carbide end mills feature 4-8 flutes, lengths up to 12xD reach, and coatings like AlTiN or TiSiN for heat resistance up to 65 HRC. Variable pitch reduces chatter, while unequal flutes ensure smooth entry in trochoidal milling paths. ToolsEngg.com offers diameters from 1mm to 25mm with necked shanks to prevent rubbing.

Key Advantages

Long reach designs access deep pockets without tool collisions, cutting cycle times by 40% versus short tools. High helix angles (45°) promote chip evacuation, extending life 3x in dry machining. Uneven flute spacing delivers mirror finishes at high feeds, ideal for semi-finishing hardened D2 or H13.

Applications in Hard Milling

Essential for injection molds, forging dies, and turbine blades requiring 0.01mm tolerances in narrow slots. They excel in ramping, helical interpolation, and 3D contouring of tool steels up to 62 HRC.