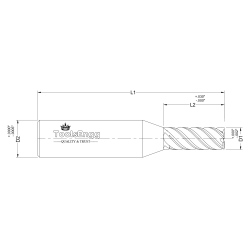

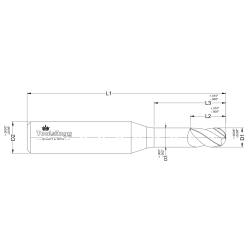

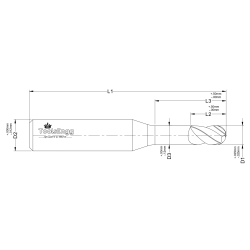

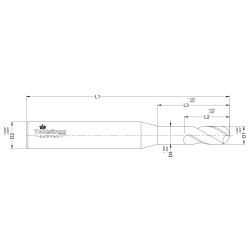

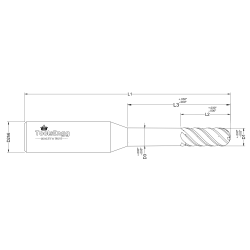

Long reach end mills are specialized milling cutters with extended flute lengths relative to their diameter, enabling access to deep cavities and narrow spaces beyond the reach of standard end mills. They maintain rigidity through reduced neck diameters and reinforced cores, minimizing deflection during precision operations.

Design Features

These tools feature extra-long flutes (often 4xD to 10xD or more), variable helix angles for vibration reduction, and coatings like TiAlN or DLC for heat resistance and longevity. Available in square end, ball nose, or corner radius profiles, they come in 2- to 5-flute configurations optimized for materials from aluminum to hardened steels. Coolant-through options and unequal flute spacing enhance chip evacuation and stability in extended applications.

Key Applications

Long reach end mills excel in deep pocketing, cavity milling, and contouring in mold and die making, aerospace turbine blades, and medical implants. They handle thin-wall machining, engine components, and composites in automotive and electronics industries where standard tools deflect. Ideal for titanium, Inconel, and hardened steels (HRC 50+), they enable intricate 3D detailing without secondary setups.

Advantages Over Standard End Mills

The extended reach reduces tool changes and machining time in deep features, while anti-chatter geometry supports higher feed rates and smoother finishes. They offer superior rigidity for high-speed machining, extended tool life in tough materials, and better access to hard-to-reach areas, boosting productivity in CNC operations.