Imperial Long Reach End Mills: Extended Precision at ToolsEngg.com

Imperial long reach end mills provide superior access to deep cavities and pockets in CNC milling, sized in inches for American-standard machining. ToolsEngg.com offers these carbide tools for mold makers, aerospace fabricators, and exporters needing precise finishes in confined spaces.

What Are Imperial Long Reach End Mills?

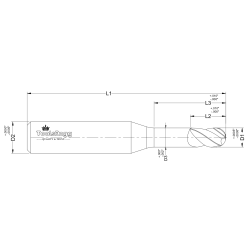

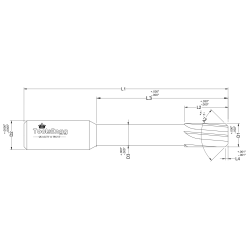

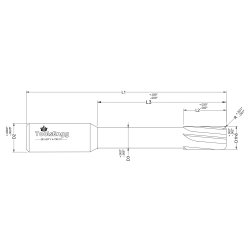

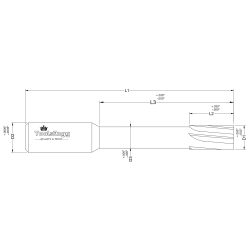

Measured in fractional and decimal inches (e.g., 1/8", 0.065" dia), these end mills feature extended flutes up to 12xD length-of-cut with reduced necks to avoid shank rubbing. Available in 2-4 flutes, AlTiN coatings, and 30°-45° helix angles, they suit steels, aluminum, and composites. ToolsEngg.com stocks series like SGS Micro M3S for micro-features down to 0.010" diameters.

Key Advantages

Long reach capability eliminates multiple setups, reducing cycle times by 30-50% in 3D contouring. Variable flute spacing damps vibration for mirror finishes (Ra 0.8µm), while high helix aids chip evacuation in dry or MQL conditions. Necked designs maintain rigidity, supporting aggressive feeds up to 200 ipm without deflection.

Applications in Manufacturing

Ideal for deep-rib molds, engine ports, and turbine slots requiring 0.001" tolerances. They excel in ramping, trochoidal milling, and helical boring of hardened alloys up to 55 HRC, supporting high-volume export production.