Plastic Cutters Long Reach End Mills: Clean Precision at ToolsEngg.com

Plastic cutters long reach end mills excel in machining plastics, composites, and soft materials with extended flutes to reach deep cavities without deflection. ToolsEngg.com supplies these specialized carbide tools for prototyping, aerospace panels, and medical device manufacturing, ensuring burr-free finishes.

What Are Plastic Cutters Long Reach End Mills?

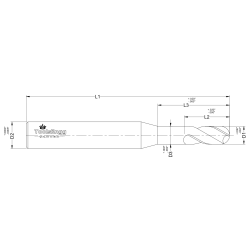

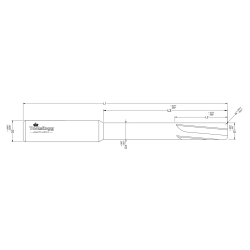

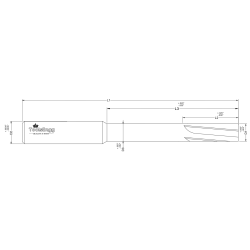

Designed with 1-2 flutes, high helix angles (45°-60°), and polished surfaces, these end mills feature extended lengths up to 10xD with reduced necks for clearance. Diameters range from 1mm-20mm, optimized for low-friction cutting in acrylics, Delrin, PVC, and carbon fiber. ToolsEngg.com offers uncoated or diamond-like carbon (DLC) variants to prevent material buildup.

Key Advantages

Single or double-flute geometry maximizes chip evacuation, reducing heat and melting in thermoplastics for superior surface quality (Ra 0.2µm). Long reach accesses intricate molds and ribs, cutting cycle times by 50% versus standard tools. Sharp, honed edges minimize burrs and delamination, ideal for high-RPM (20,000+ SPM) dry machining.

Applications in Industry

Perfect for circuit board drilling, enclosure milling, and orthopedic implants requiring precise slots and contours. They shine in 3D surfacing composites for automotive interiors and drone frames, supporting clean exits in stacked laminates.