Variable helix long reach end mills combine advanced geometry with extended reach to deliver stable, high-performance machining in deep pockets and hard-to-access areas. These premium carbide tools from ToolsEngg.com are ideal for mold making, aerospace, and precision component manufacturers seeking higher feeds, better finishes, and reduced chatter.

What Are Variable Helix Long Reach End Mills?

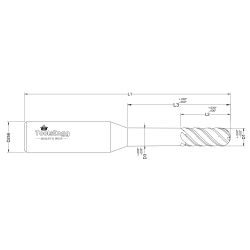

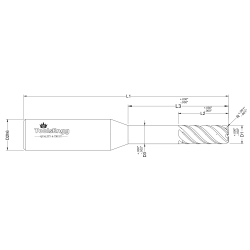

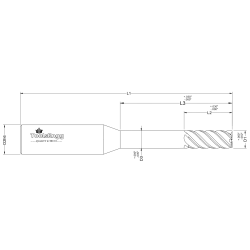

These end mills feature flutes with varying helix angles along their length, typically around 38°–41°, which disrupt cutting harmonics and significantly reduce vibration. Long reach designs incorporate reduced neck diameters and extended lengths-of-cut (often 3xD and beyond) for deep cavity access while maintaining rigidity and avoiding heeling.

Key Performance Advantages

Variable helix geometry spreads cutting forces, enabling higher speeds and feeds with smoother cutting action and improved surface finish, often eliminating secondary finishing passes. Users benefit from lower chatter, longer tool life, and higher material removal rates, especially in steels, stainless steels, and heat-resistant super alloys when paired with modern AlTiN or Nano coatings.

Typical Applications

These tools excel in 3D contouring, pocketing, and slotting in thin-walled or deep features where stability is critical. They are widely used on high-speed machining centers for dies, injection molds, and structural aerospace parts requiring tight tolerances and superior surface quality.